Prototype Your Ceramic Part Quickly

Are you facing challenging timelines for precision parts in the race to produce a prototype? If you have a drawing or a design, Ferrotec can help. We can fabricate parts from your designs quickly using our rapid prototype ceramics. By combining our precision manufacturing capabilities with our proprietary machinable ceramic materials, we can help you prototype designs fulfill specialized, small quantity requirements.

Benefits

- Access to a variety of machinable ceramic materials including Photoveel or our unparalleled Photoveel II series material.

- Integrated supply: material manufacturing + machining service

- Precise machining, micro holes, controlled CTE and high fracture toughness

- Minium order quantity: 1pc

- Competitive lead times

Applications

- Semiconductor equipment parts

- Semiconductor inspection parts

- Laser equipment parts

- Vacuum equipment parts

- Thin film deposition equipment parts

- Linear motor parts

- Heat-insulating parts

- FPD process equipment parts

- Adhesion equipment parts

- Positioning parts

- Sensor parts

- Analysis equipment parts

- Ultrasonic generator

- Electric-insulating parts…etc

Ceramic Expertise

Ferrotec’s machinable ceramics offer superior machinability. While our machinable ceramics can processed using standard machining tools, Ferrotec also offers ultra-high precision machining.

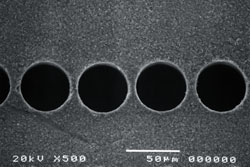

Minute Hole Drilling

We provide minute hole drilling on the machinable ceramic plate.

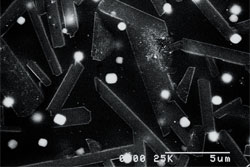

Structure of Photoveel

Minute Hole Drilling (Photoveel)

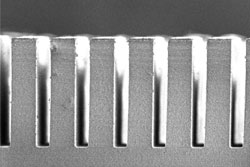

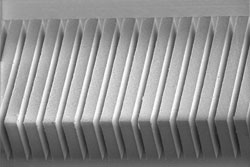

Minute Groove Processing

We can process a minute, highly accurate groove to machinable ceramics.

We have various options according to customer’s utilizing purposes. Please consult us about anything including complicated form and ultra high precision machining requirements.

Grinding Equipment

- Rotary grinder

- Machining centre

- Cut machine

- Others

- General plain grinder

- Dicing saw

- Lapping machine

- Grinding centre

- Cylindrical grinder

- Washing equipment

Inspection Equipment

- 3D coordinate measuring machine

- Surface roughness measuring machine

- Non-contact shape measuring machine

- Others

Minute Hole Drilling

| Min. hole size | 30μm (Thickness 0.3t) |

| Hole diameter accuracy | 5μm |

| Pitch accuracy | 5μm |

Photoveel

| Dimensional tolerance—general machining | According to JIS B 0405 medium grade | |

| Dimensional tolerance—precision machining | 5μm or less (flatness, parallelism, etc.) | |

| Microscopic hole drilling | Minimum φ45μm (thickness 0.3mm), diameter and pitch tolerance ±5μm | |

| Thread cutting | Minimum M2, HELISERT minimum M2.5 | |

Send Your Questions, Your Drawings, or Your Parts and We Can Quote.

Ferrotec Offices

USA & Canada

Ferrotec (USA) Corp.

Ceramics Department

566 Exchange Court

Livermore, CA 94550

(408) 964-7700

Fax: (408) 964-7775

Ceramics Inquiry Form

Do You Need More Information?

Find out more about Ferrotec’s ceramic manufacturing capabilities