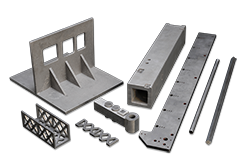

Al-SiC Metal Matrix Composite Ceramic Material

Ferrotec’s metal matrix composites take advantage of various material mixes to deliver unique material properties and performance characteristics. The material properties of Aluminum—Silicon Carbide metal matrix composites make it a good solution for large size products. Al-SiC metal matrix materials are good for contributing to weight reduction and provide excellent damping for high speed and precise equipment motion applications like robot parts.

Benefits

- Light weight

- High stiffness

- Low thermal expansion

- High thermal conductivity

- Excellent mechanical damping

- Facture toughness

- Near net shape process allowance

Applications

- Semiconductor equipment parts

- Semiconductor inspection parts

- Display equipment parts

- Precision equipment parts

- Heat sinks

Al / SiC Material Properties

| Al75 / SiC25 | Al70 / SiC30 | Al60 / SiC40 | ||

|---|---|---|---|---|

| Composition (vol%) | Al 75 SiC 25 |

Al 70 SiC 30 |

Al 60 SiC 40 |

|

| Density (g/cm3) | 2.8 | 2.8 | 2.9 | |

| Young’s modulus (Gpa) | 115 | 125 | 150 | |

| Young’s modulus / density (Gpa ⋅ cm3/g) | 41 | 45 | 52 | |

| Flexural strength (MPa) | – | – | – | |

| Coefficient of thermal expansion (1/°C×10-6) | 15 | 14 | 13 | |

| Thermal conductivity (W/m×K) | 145 | 150 | 155 | |

Do You Need More Information?

Find out more about Ferrotec’s ceramic manufacturing capabilities