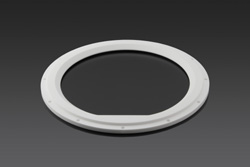

Alumina Ceramic Materials in Multiple Grades of Purity

Alumina ceramics are one of the most robust ceramics available. Alumina ceramics have outstanding properties that make them one of the most widely used ceramics for structural, wear, and corrosive environments. Additionally, with their exceptional electrical properties, high purity alumina ceramics are one of the preferred materials for semiconductor chamber applications.

Applications

- Chamber parts in semiconductor equipment

- Wafer transfer parts

- FPD manufacturing equipment parts

- Heat resistant and electrical insulation parts

Properties

| AS999 | AG999 | AM997 | |||

|---|---|---|---|---|---|

| General properties | Characteristics | High purity | Plasma-resistant | General grade | |

| Main component purity (wt%) | 99.99 | 99.9 | 99.7 | ||

| Color | White | Whitish-yellow | Whitish-yellow | ||

| Density (g/cm3) | 3.95 | 3.93 | 3.93 | ||

| Water absorption (%) | 0 | 0 | 0 | ||

| Mechanical properties | Bending strength (MPa) | 390 | 390 | 390 | |

| Young’s modulus (GPa) | 380 | 380 | 375 | ||

| Vickers hardness (GPa) | 18 | 17 | 18 | ||

| Thermal properties | Max. operating temperature (°C) | 1600 | 1600 | 1600 | |

| Coefficient of thermal expansion (1/°C×10-6) | RT~500°C | 7 | 7.4 | 7 | |

| RT~800°C | 7.7 | 8.1 | 7.6 | ||

| Coefficient of thermal conductivity (W/m×K) | 33 | 30 | 33 | ||

| Thermal shock resistance ΔT (°C) | 200 | – | 200 | ||

| Electrical properties | Volume resistivity | 25°C | 1015 | 1015 | 1016 |

| 300°C | 1012 | – | 1013 | ||

| 500°C | 109 | – | 1010 | ||

| 800°C | 107 | – | 109 | ||

| Dielectric constant | 10GHz | 9.9 | 9.7 | 9.7 | |

| Dielectric loss (×10-4) | 0.5 | 6 | 1 | ||

| Q factor (×104) | 2 | 0.2 | 1 | ||

| Dielectric breakdown voltage (KV/mm) | 18 | 17 | 18 | ||

Do You Need More Information?

Find out more about Ferrotec’s ceramic manufacturing capabilities